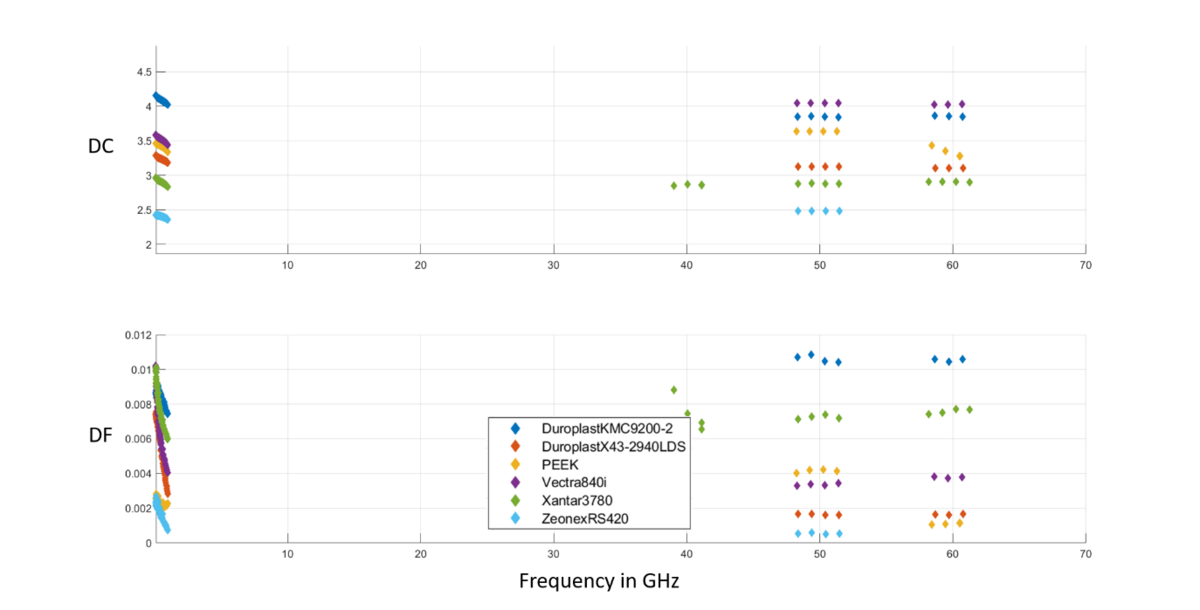

The complex permittivity is the main influencing factor of typical dielectric materials in an RF application. Besides the frequency related geometric dimensions the losses induced in the substrate material can be derived from the complex permittivity. Due to the fact that the dielectric properties are frequency related an evaluation has to be done depending on the frequency range covered by a specific application.

Fig. 1 shows the relative permittivity values (dielectric constant DC) for different LDS materials with the associated dielectric losses (dissipation factor DF, equals loss tangent in complex permittivity). With materials like Vectra E840i (a Liquid Crystal Polymer, LCP), a polyetheretherketone (PEEK), Zeonex RS420 (a cyclic Olefine Copolymer, COP), different Xantar materials such as LDS 3730,3760 or 3780 (Poly Carbonate based, PC) or different Duroplast based materials many different material categories were characterized. The measurements in the mmWave range are carried out using an open resonator. The measurements around 1 GHz were made using an impedance analyzer to measure capacitance and conductance of a dielectric test sample. The permittivity values are in a range of about 2.4 to 4.2 for frequencies from 1 GHz to 60 GHz. These values do not differ significantly from that of typical RF substrate materials. The measured dissipation factor is in a range of < 0.001 to 0.011. The dissipation factor of most of these LDS materials is slightly higher than for high performance RF materials. This shows that LDS materials are generally suitable for RF applications even in the mmWave domain. Similarly to a typical RF laminate, the choice of a LDS substrate material must be made by considering the specific application, taking into account both the RF and mechanical requirements.